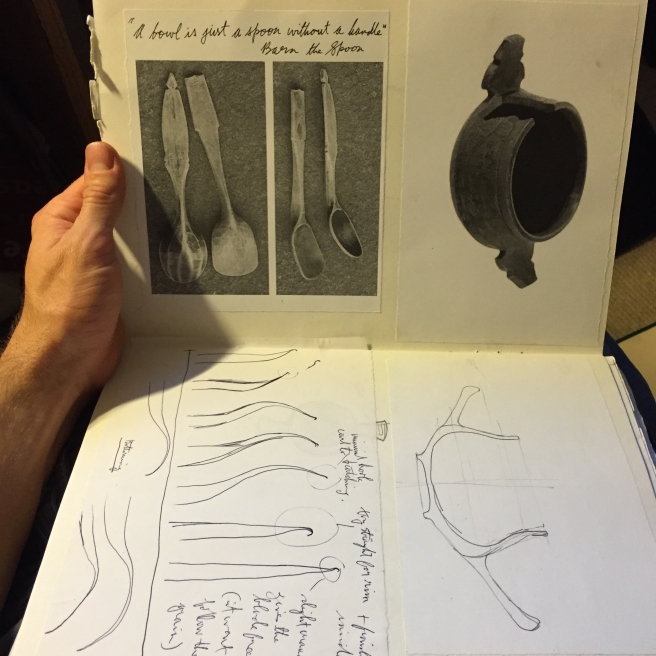

I’ve been going back over some old notebooks recently and came across this page. The quote over the image of Fritiof’s spoons reads “a bowl is just a spoon without a handle”.

I remember when I first met Barn the Spoon in Abney Park Cemetery, probably almost 7 years ago now. That’s when he admonished me, via the quote above, for wanting to make bowls on a pole lathe. We were both trying to make medieval style eating spoons at the time and exchanged notes, although he was certainly taking a much closer look than me. He was making a lot of spoons at the time, street selling and camping his way around the country. Of course Barn has since gone on to many amazing spoon carving achievements and done great things for the whole scene in the UK. Not least his role in establishing spoonfest with Robin Wood and co. This year I made it to spoonfest for the 3rd time and was even lucky enough to do a course with Barn. I don’t have the time to to a full spoonfest blog post, but all I will say is it was great craic. After missing it the last two years I was delighted to be able to make a return, met lots of great people and caught up with old friends. Just sorry I didn’t get around to talking to everyone.

Ahead of Edale I had a brief episode of spoon carving, the first in about 18 months, to at least be somewhat prepared. I took a few photos of the process:

I was glad I had done this bit of carving as I managed to sell two of the six spoons I brought, which paid for my bus ticket. I do love making spoons but when I first started green woodwork I made tonnes to sell and got a bit sick of them. Going back to spoonfest and seeing all the amazing work that people are doing now has been a great inspiration and motivation to start making a few spoons again more regularly. I also returned to my favourite spoons (mostly Fritiof Runhall’s) in Robin Wood’s collection that he kindly puts out on display for the weekend. While there I felt ashamed that I don’t own more from different makers, but when I returned home and checked the kitchen I realised I did at least have a few. I will definitely be building on this little collection now!

Carving spoons was really the gateway drug into green woodwork for me, and my enthusiasm for them has fully returned. In reality it is mostly down to the people I have met along the way that I am motivated to keep doing woodwork and that only started to dawn on me properly at spoonfest.

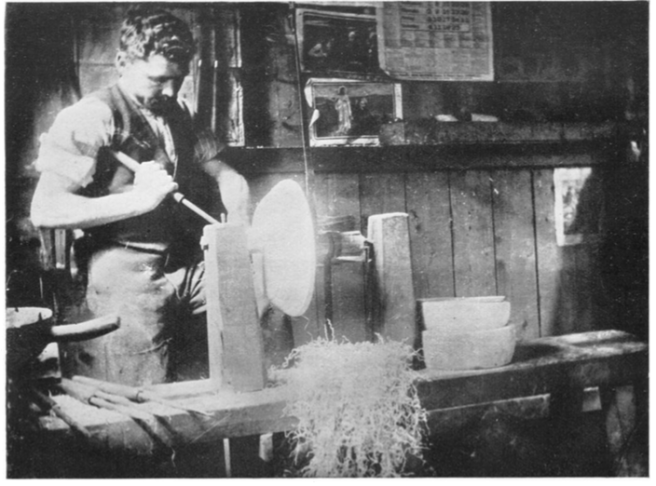

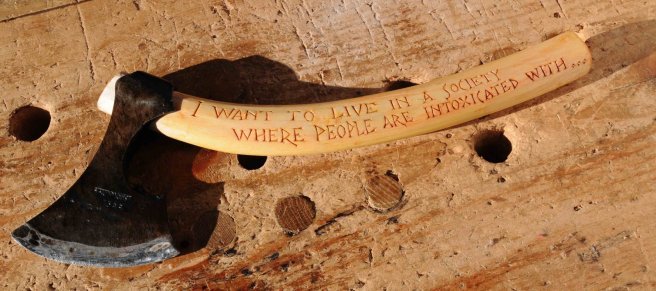

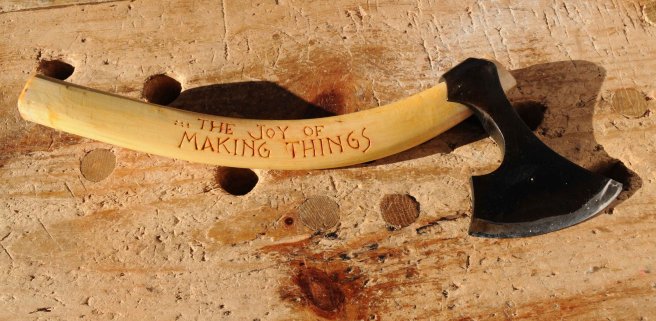

My final thought for this blog post is stimulated by a poem Iorwerth Peate included in his 1933 paper titled “Welsh Folk Industries” (also containing a lovely photo of a pole lathe turner that I have inserted below). The world would be a better place if we made more stuff, furnishing our lives and environment directly with the products of our own hands.

Some beautiful images are conjured in this odd poem:

There is no point in work

unless it absorbs you

like an absorbing game.

If it doesn’t absorb you

if it’s never any fun,

don’t do it.

When a man goes out to work

he is alive like a tree in spring,

he is living, not merely working.

When the hindus weave thin wool into long, long lengths of stuff

with their thin dark hands and their wide dark eyes and their still souls absorbed

they are like slender trees putting forth leaves, a long white web of living leaf,

the tissue they weave,

and they clothe themselves in white as a tree clothes itself in its own foliage,

As with cloth, so with houses, ships, shoes, wagons or cups or loaves.

Men might put them forth as a snail its shell, as a bird that leans its breast against its nest, to make it round,

As the turnip models its round root, as the bush makes its own flowers and gooseberries, putting them forth, not manufacturing them,

And cities might be as once they were, bowers grown out from the busy bodies of people’

And so it will be again, men will smash the machines.

At last, for the sake of clothing himself in his own leaf-like cloth tissued from his life,

and dwelling in his own bowery house, like a beaver’s nibbled mansion

And drinking from cups that came off his fingers like flowers off their five-fold stem,

he will cancel the machines we have got.

D H Lawrence 1885-1930

anthologised in ‘A Book of Comfort‘ by Elizabeth Goudge, Fontana 1968

Box bits have been cluttering my shed for ages, so I was delighted to finally nail them together and get rid of one of them into the house.

I made a short time lapse of the carving of the box sides, which were lined up side by side. Now that I am familiar with the pattern I will be able to carve all three sides at once. This is very fast and efficient as the chisel cuts in the design repeat very regularly.

Looking at the box the carving stands out as the main element. However, the rest of the construction is very time consuming and fiddly when you’re as disorganised as me. When using wood directly from a split green log there is a lot of work in preparing the stock for each individual plank. Most of the boards in the till were planed down from scrap pieces covered in practice carvings.

The wide sawn pine boards for the lid and base also have to be flattened and their edges shaped. Cleats nailed to the boards help reduce movement in them. In this case they also attach the lid to the box hinges (pegs projecting from the back board). The only holding devices I have on the whole bench are holdfasts and the planning stop. Happening across a Chris Schwarz post, which refers back to an earlier one from Richard Maguire (sorry lads can’t find the links) detailing a kind of wood pincher board, was very well timed and a big help. This little trick essentially removes any vague need I thought I had for a tail vice. I like that my bench is basically a block of wood with some holes in it and I plan to keep it that way until a job absolutely necessitates new bench appendages.

Lastly, photos of the finished box. I rarely try and take good quality pictures of my work so I took a few extra ones of other turned work that was to hand while I was at it.

Just before leaving I asked Tamás about the decoration of the big chest he was working on, as it had to be finished for a customer within a few days. He will take some careful time and thought over the carvings, which are executed freehand, or with straight line and compass, but otherwise done freely and from memory. They carry complex meaning relating to both faith and culture and discussion of this makes up a large portion of the first book he published. It is essential for Tamás to get them right. Since I left he forwarded me photos of the completed decoration.

Still at a very early stage on my journey into woodwork, for various reasons I have moved ahead in fits and starts, following multiple threads. Things have often happened in short intense bursts of productivity depending on the circumstances. Sometimes I have to engineer these circumstances by booking myself on a course or going off on some kind of journey. These past five days have been a typical example, although I have a feeling I will be able to keep the momentum gained up for a fair while longer than usual.

Against the odds I managed to get in the shed for a second day in a row today and advance on the carving from the practice runs yesterday. This time I was working on the front board of a big box and it is the very last bit of oak I have left until I buy another tree. So I was twoing and froing lots before finally striking some chisels into it today.

I was able to adapt the practice carvings from yesterday directly onto the board, using them as a reference as I went. Here are a series of photo’s showing how the layout advanced. After initially being terrified of making a mistake and going very slowly, I started to get a feel for the repetition in the pattern and it flowed smoothly. I can imagine back in the day these were made at high speed.

After everything is struck out with the chisels the last task is to remove all the background. That is when the whole pattern comes alive. It is ridiculous it has taken me a year since going on the course with Peter Follansbee to do this but better late than never. I am massively indebted to him for the way he has made this woodwork accessible to amateurs like me.

Today was my first go carving some patterns I am a big fan of. At first glance they look complicated, then on inspection you realise they are quite easy to lay out and cut, only to mess them up a lot when trying to do them for real. I have four really nice wide oak boards that are going to make another box and I intend to cover them in this strapwork. I knew I would struggle to cut these right first time though so planed off some old carvings from a board to do a practice run on today. I am determined to get the hang of these, from what I can gather once you get the basic pattern and layout you can play with the design a lot and it becomes very versatile.

I don’t want to post pictures belonging to anyone else so please have a look at Peter Follnsbee’s article about this design to see the real deal:

https://pfollansbee.wordpress.com/2013/02/08/strapwork-carving-designs/

For me spacing the pattern out has been the main difficulty. Because the whole pattern is laid out based on the curves of the chisels struck into the wood, rather than the free cuts of a v-tool, you are somewhat limited by the chisels themselves. I did try to pick Peter Follansbee’s brain about these when I went on his course last year, and his main bit of advice was “start in the centre and work your way out, it’s real simple”. After a false start and re-planing the board down, I eventually got to this point (in the photo below). I started at the centreline of the board, and then worked my way out creating sections based on the diameter of the arches at the top and bottom of each section. This seems to be the key dimension in determining the layout, although it is never actually measured, just laid out on the wood one chisel strike after the next. Once the width of the first arch was defined, I marked out a series of vertical lines to section off all the rest of the pattern out to the board ends.

Once I had got the hang of striking out the pattern in the wood I practiced some bits that were not working so well, and removed some of the background. So this looks like a real mess in the end but hopefully I will be able to avoid the same mistakes on the finished piece now that it is clearer in my head.

To me this is magic, I love techniques that bind wood together without the need for any other material. There are many different ‘aha’ moments one has when meandering through the vast world of green woodwork and one such moment was seeing and understanding a draw bore mortise and tenon joint for the first time. Here are some oak trenails holding together a coffee table frame I recently made:

A quick update on another style of flask I’ve been making, this one much more closely replicating the style of the Romanian turner filmed by Stuart King: https://www.youtube.com/watch?v=XEibt31OlCA

These two photo’s show the overall shape being turned on the first axis, then the mandrel being sawn off. It is then repositioned perpendicular to the face of the flask where the opening for hollowing is located.

Turning on the second axis mainly concerns the hollowing, this flask is a smaller diameter but much deeper form than the last one I made.

You can see exactly where the wood for the flask came from below. It is sitting on top of the 1/16th section of the oak log it came from. It’s a tight fit to make the most of the wood. The back of this flask will have a facet left from the original surface of the split wedge of oak, the marks from the mandrel tangs will get carved away.

Seeing this picture of a window in Reginald’s Tower makes me wonder how many medieval travellers passed through Waterford with a wooden flask at their side? I wonder did one of the many pole lathe turners Waterford had in its past ever make flasks?